Cleaning and pickling sections for metal strip

(STAINLESS STEEL, ALUMINIUM AND ITS ALLOYS, COPPER AND ITS ALLOYS)

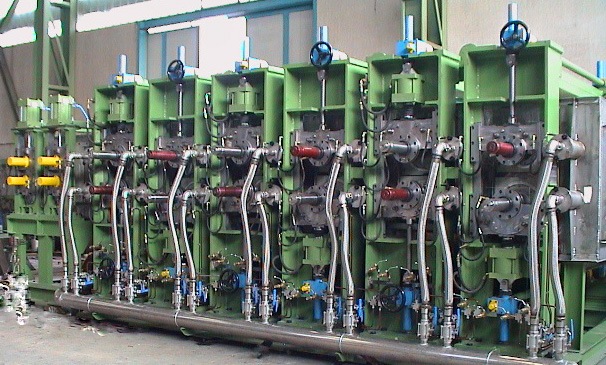

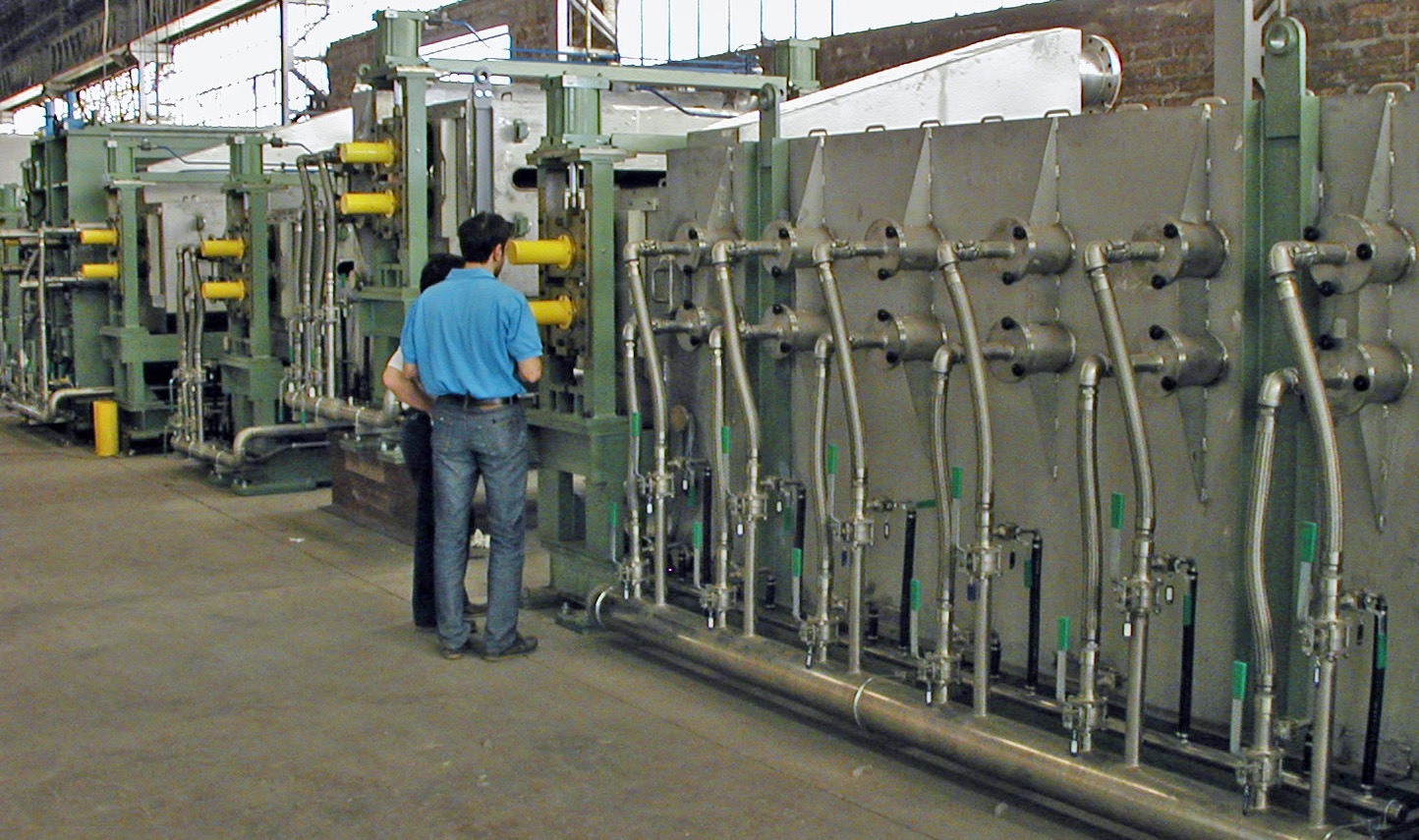

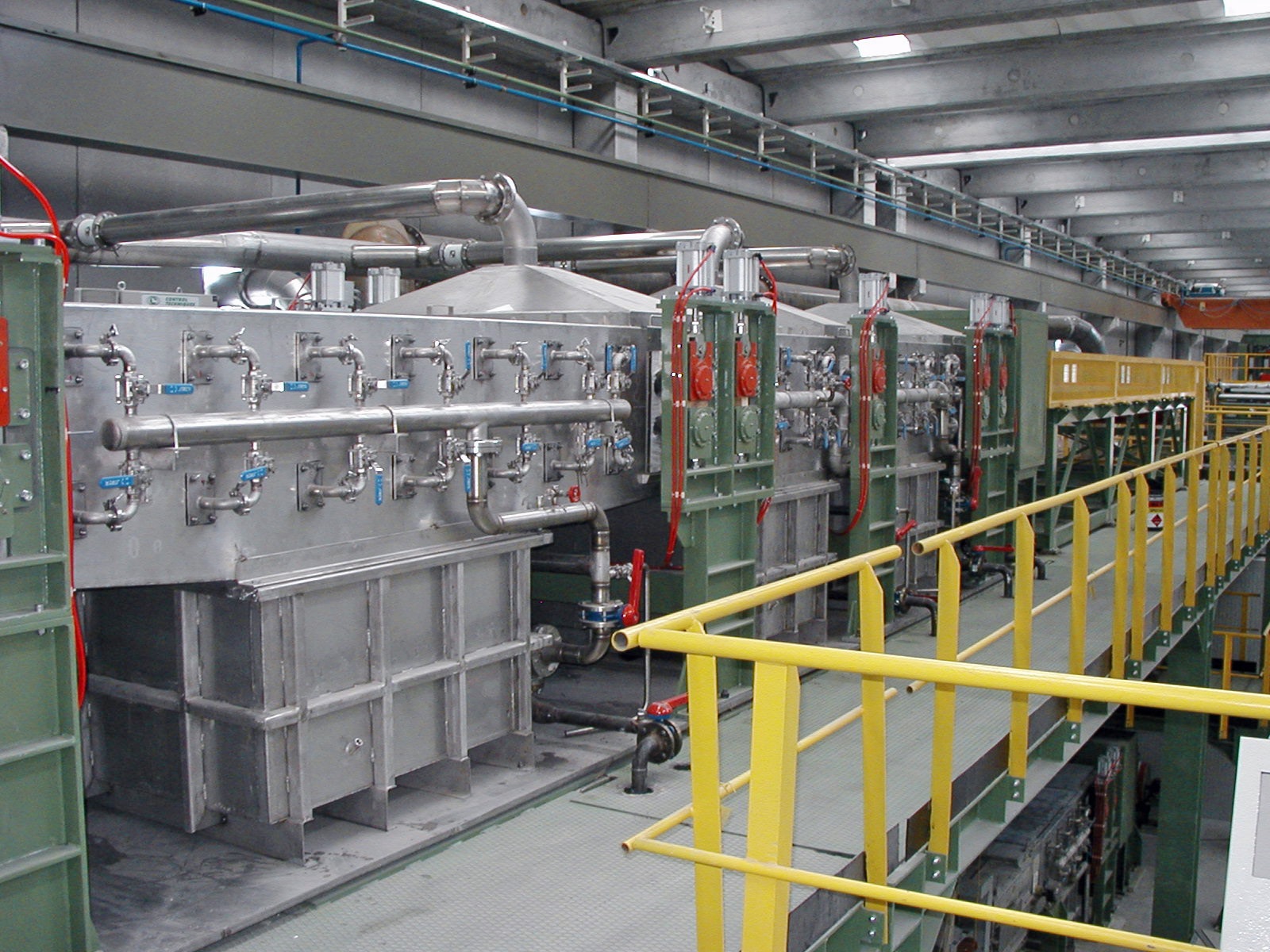

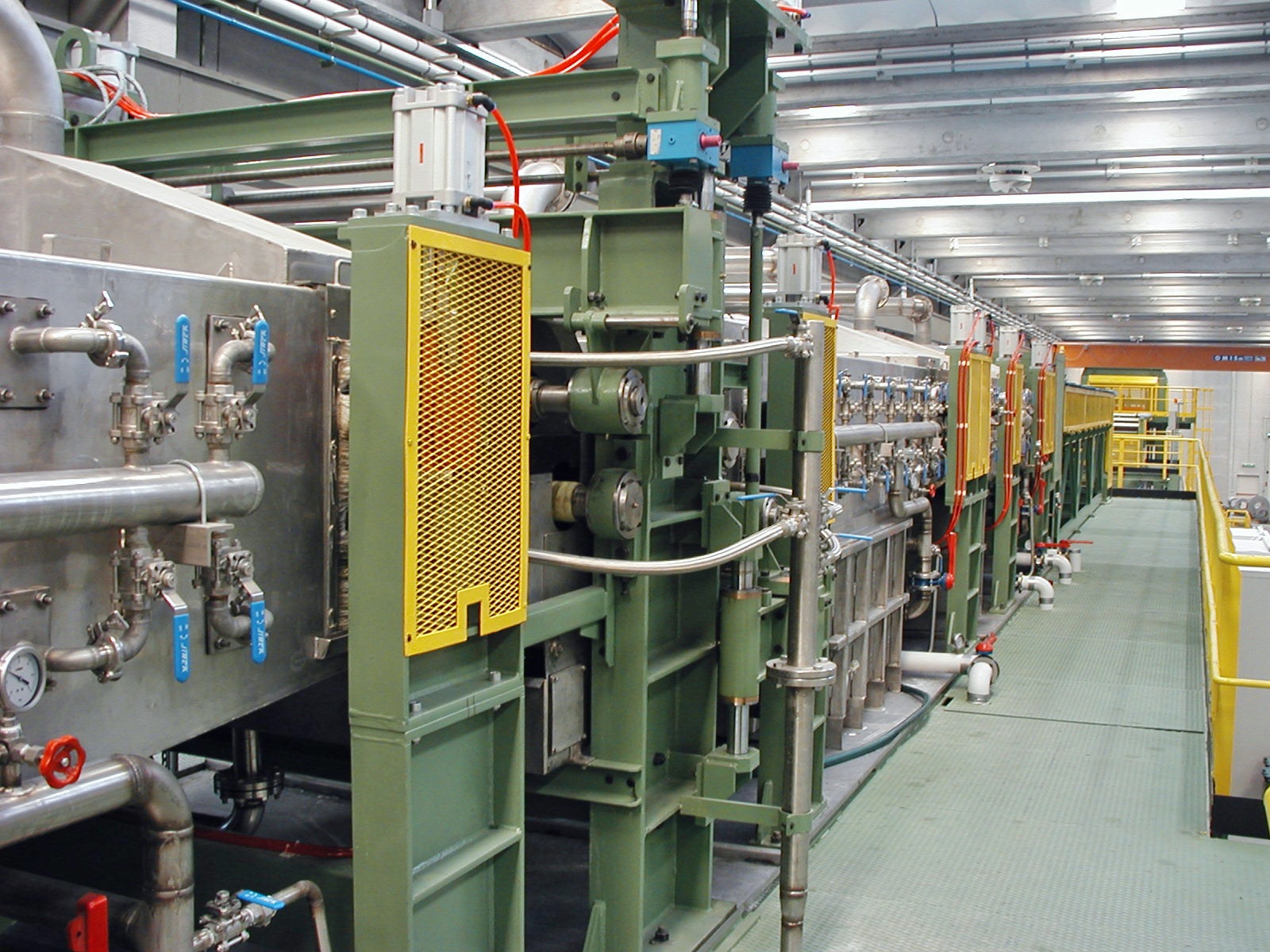

Cleaning and pickling sections for metal strip, spray type, to be installed in continuous

or push-pull lines.

Strip thickness range: from 0,1 mm (aluminium) to 6 mm (stainless steel)

Strip width: from 400 mm to over 1600 mm

Strip velocity: over 100 m/min

The following equipment may be included, according the process requirements and/or the Customer specifications:

completely made of stainless steel (1.4306, 1.4435 or equivalent) and skid mounted

brushing units with polypropylene, nylon, SiC, AlO brushes, velocity up to 1.200 rpm, balance grade 6.3, quick exchange system.

high pressure spray system (up to 120 bar)

filtration system

degreaser and acid dosing system

demineralised water production plant – reverse osmosis type

ultrafiltration plant.

Copper alloys Cleaning and Pickling Section

*100 m/min * 0,1-3,5 mm * 500 mm

Copper alloys Cleaning Section

*100 m/min * 0,1-4,5 mm * 600 mm

Stainless Steel Bright Annealing Line,Cleaning section

* 40 m/min * 0,1-1,2 mm * 1.250 mm

Stainless Steel Bright Annealing Line,Cleaning Section

* 100 m/min * 0,1-1,2 mm * 1.550 mm

Copper alloys Cleaning and Pickling Section

*100 m/min * 0,1-4,5 mm * 1.300 mm

Copper alloys Cleaning and Pickling Section

*100 m/min * 0,1-4 mm * 550 mm

Coating Line (stainless steel, aluminium), Cleaning Section

* 35 m/min * 0,1-1,2 mm * 1.550 mm